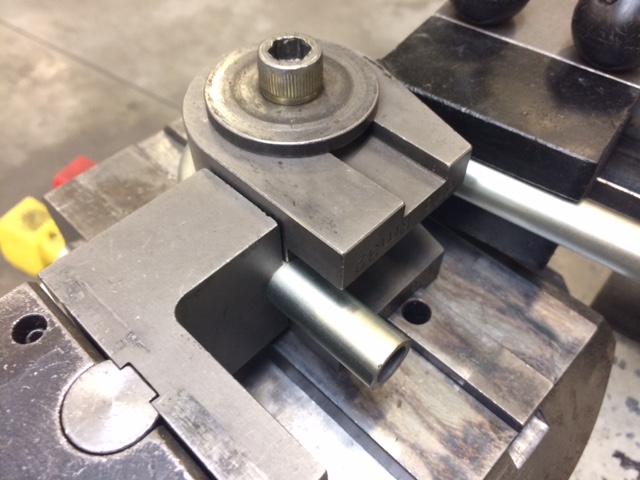

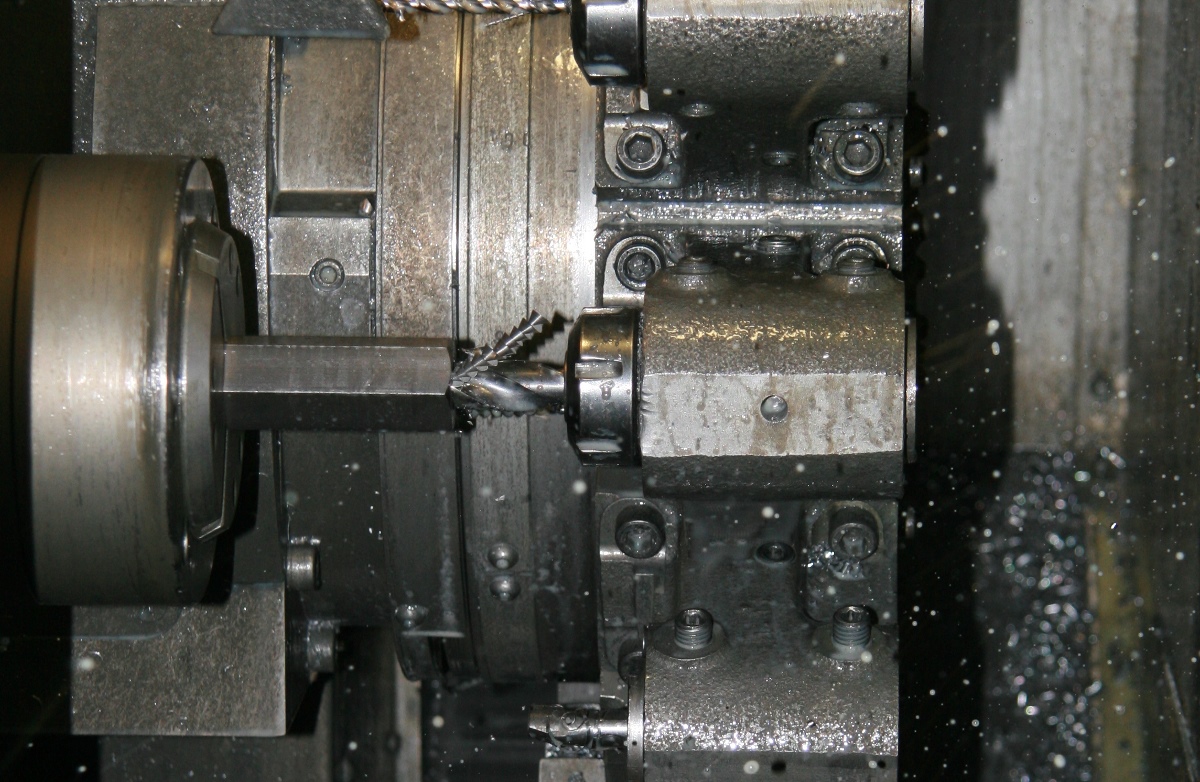

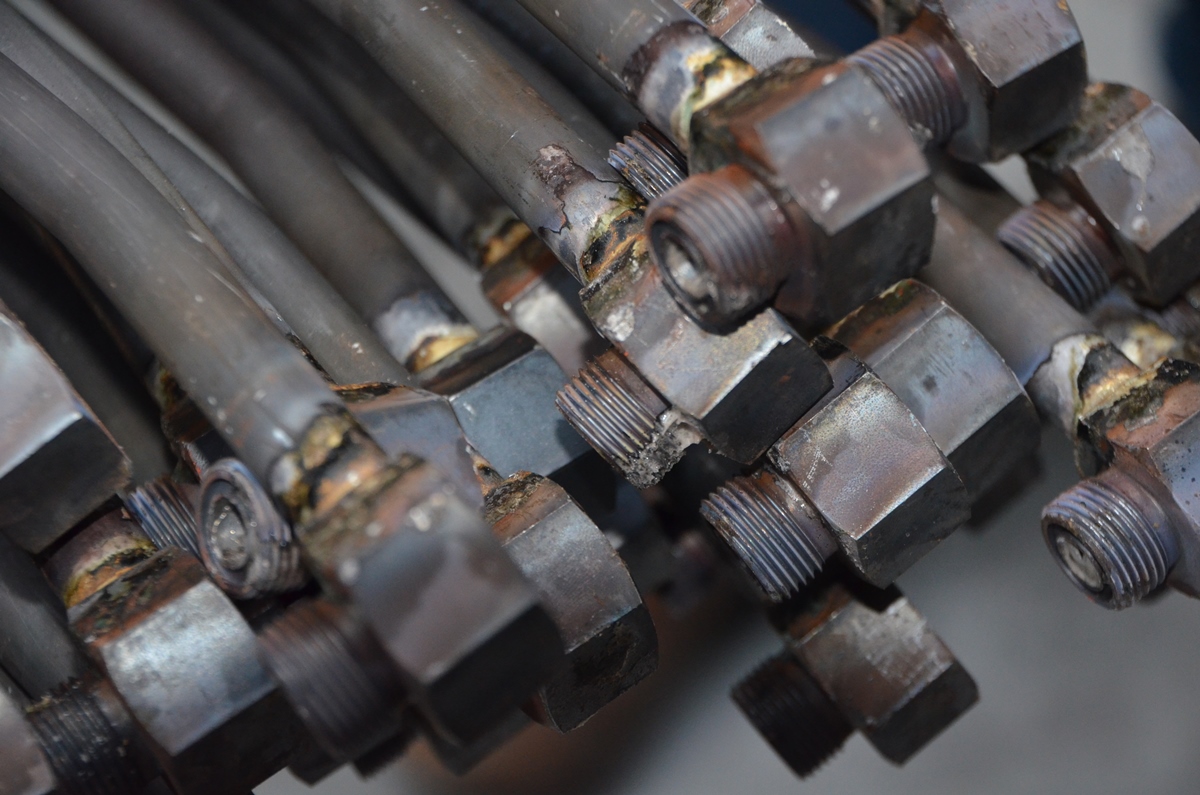

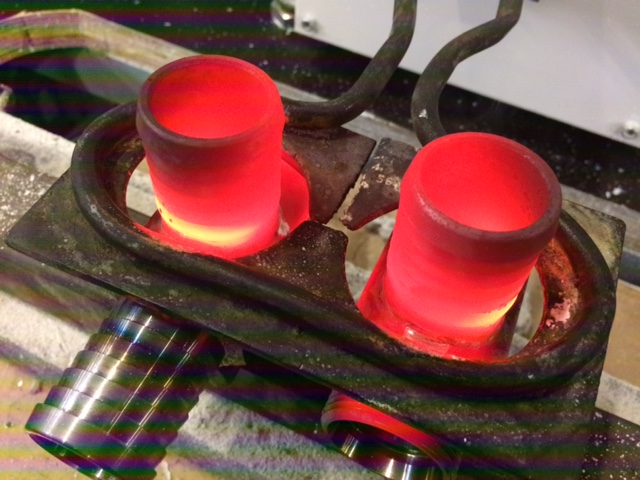

Custom

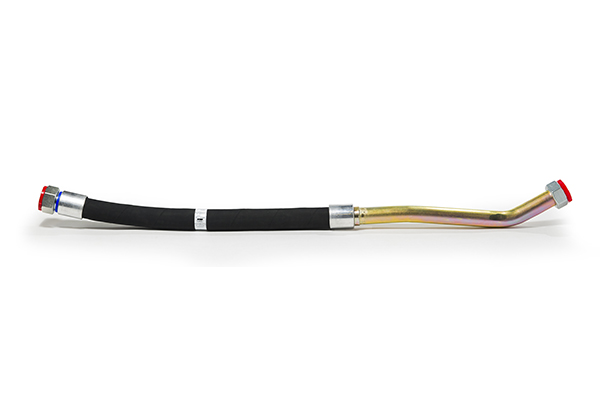

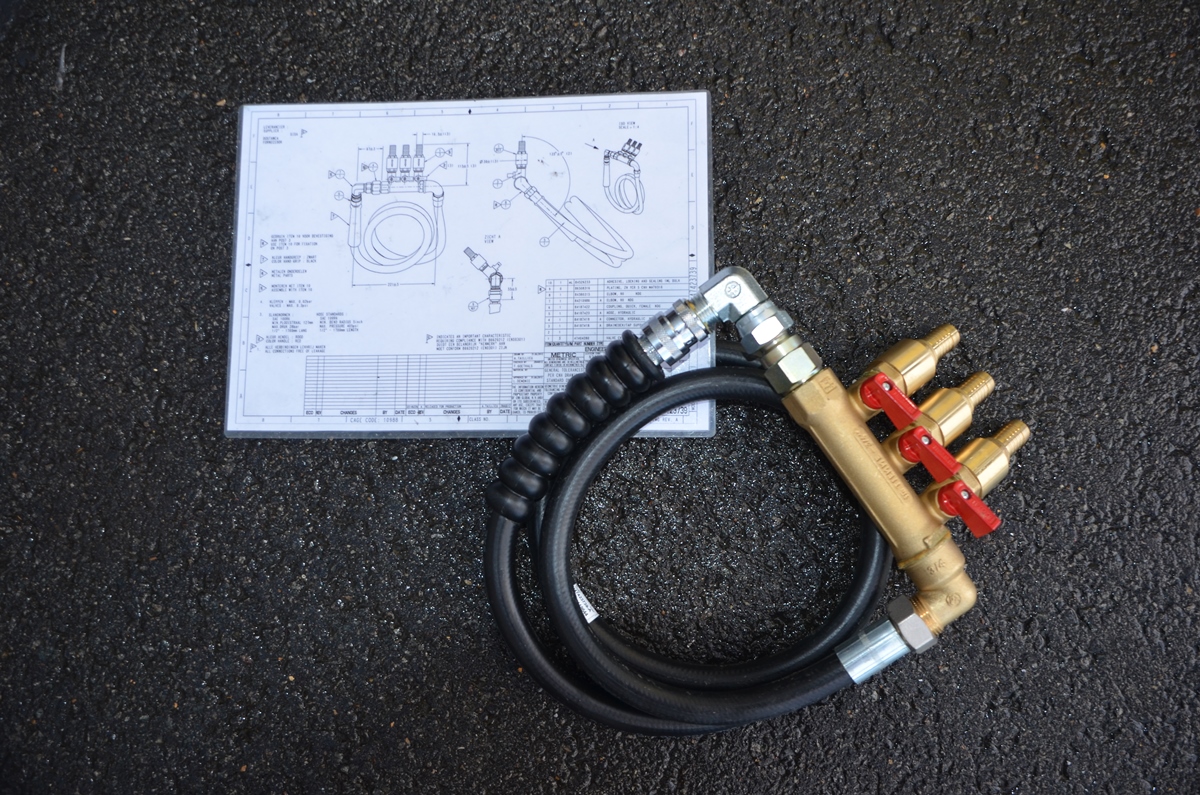

Thanks to its specialized machinery, SISA NV is able to deliver tailor-made parts according to the customers’ wishes. These parts are fabricated on the turning centers, or it could be tubes on the bending machine, brazed parts, hose/tube assemblies or parts covering all of the above techniques. Intensive collaboration with the customer from design to final product, leads to unique highly specialized products.